As the EV industry pushes toward lighter, faster, and more efficient electric propulsion, specialist manufacturers and low-volume OEMs face a unique challenge: how to access cutting-edge powertrain technology without the enormous cost of building it themselves. That’s where Everrati’s Powered by Everrati (PBE) division comes in. Known for transforming high-performance EV engineering into flexible, modular systems, Everrati is increasingly becoming a go-to partner for companies looking to electrify complex or unconventional platforms.

A significant step in that evolution is Everrati’s technical collaboration with Motion Applied, a global expert in high-performance electrification and control systems. Together, the two companies are combining advanced 800V Silicon Carbide power electronics with Everrati’s modular powertrain architecture. The result is a new generation of propulsion solutions that are more compact, efficient, and significantly easier to integrate across diverse mobility applications, from performance road cars and motorsport to marine, aerospace, and commercial vehicles.

A New Benchmark for Scalable, High-Performance EV Powertrains

At the heart of the partnership is the integration of Motion Applied’s 800V Silicon Carbide MCU-600 Inverter, part of the AMPEX product family, into Everrati’s next-generation modular powertrain architecture. This platform has been engineered from the ground up for rapid integration, packaging flexibility, and future-proof performance, making it ideal for specialist OEMs seeking to electrify without developing an EV platform in-house.

Why 800V Architecture Matters

As the EV industry moves beyond traditional 400V systems, 800V electrification offers major benefits:

- Faster charging and improved thermal performance

- Higher power density in compact spaces

- Reduced current for the same power output, lowering cable weight and improving efficiency

- Compatibility with next-generation motors and energy storage systems

For low-volume manufacturers, many of whom often face space constraints, unusual chassis layouts, or weight distribution challenges, an ultra-efficient, lightweight 800V solution provides a significant competitive advantage.

Engineering Validation Through the GT40 Test Programme

To validate the robustness of the combined Everrati/Motion Applied solution, the companies utilised the Everrati GT40 chassis as a demanding engineering testbed. The GT40’s architecture is notoriously complex, with extremely tight packaging tolerances and strict requirements for weight distribution and cooling. These constraints made it an ideal platform to push the boundaries of the modular system.

Through this programme, engineers proved that the MCU-600 inverter and Everrati’s powertrain modules could be integrated into one of the most challenging layouts in automotive engineering. This validation phase demonstrated:

- Precise motor control at high loads using Silicon Carbide switching

- Effective thermal management even under extreme dynamic conditions

- High torque delivery and rapid response times, essential for performance-oriented OEMs

- Seamless scalability, enabling the same inverter architecture to support varied motor configurations and voltage requirements

The successful GT40 evaluation now serves as a reference point for OEMs seeking to electrify vehicles that were never originally designed for EV propulsion.

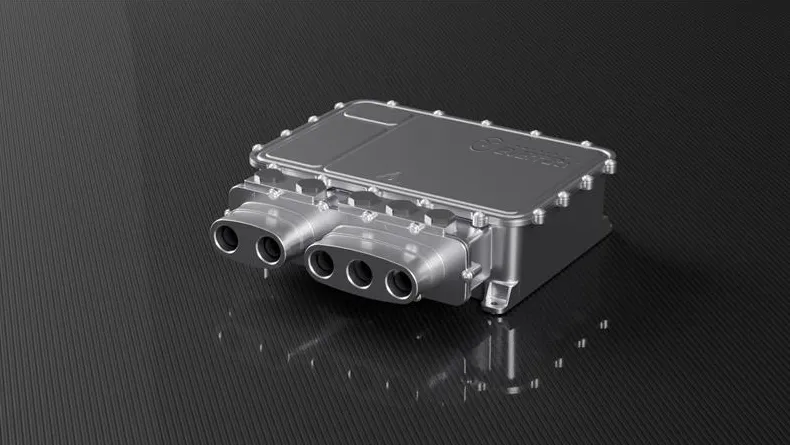

Inside the MCU-600: Advanced Silicon Carbide Power Electronics

Motion Applied’s MCU-600 inverter is a next-generation Silicon Carbide (SiC) platform engineered for exceptional efficiency, power density, and control precision. Key technical advantages include:

1. Over 400kW Peak Power Output

The inverter is capable of delivering more than 400kW per unit, enabling multi-motor configurations and supporting high-performance vehicle applications.

2. Ultra-Low Switching Losses

Silicon Carbide technology dramatically reduces switching losses compared with traditional IGBT-based inverters, resulting in:

- Higher overall drivetrain efficiency

- Reduced heat generation

- Greater range or performance for the same battery size

3. Lightweight, Compact Packaging

The minimized thermal footprint of SiC components allows for smaller housings—and in turn, more innovative mounting configurations for vehicles with unconventional chassis geometries.

4. Patented Motor Control Algorithms

Motion Applied’s proprietary control software ensures smooth torque delivery, rapid response, and high stability across a wide range of load conditions.

The integration of the MCU-600 into Everrati’s systems enables OEMs to deploy state-of-the-art EV propulsion with dramatically reduced development time.

Powered by Everrati: A Growing B2B Electrification Platform

Everrati’s PBE division has rapidly evolved into a commercial arm focused on delivering turnkey EV powertrains for manufacturers who want to enter the electric market without the cost, expertise, or risk of developing technology internally.

From battery systems and thermal management to power electronics, motor technology, and vehicle control integration, Everrati provides OEMs with a complete propulsion toolkit that is modular, scalable, lightweight and highly configurable. This makes it particularly valuable for niche performance brands, specialist vehicle builders, and companies electrifying legacy platforms.

A Future of High-Efficiency, High-Performance Electrification

The partnership between Everrati and Motion Applied showcases what the next generation of EV powertrain technology looks like: lighter, smarter, faster, and more scalable. As manufacturers across automotive, marine, aerospace, and motorsport seek flexible electrification solutions, the integration of 800V Silicon Carbide power electronics positions Everrati as a leading supplier of advanced EV propulsion systems.